Deep Foundations For The Wind Energy Movement

We are DFI, your one-stop steel piling source – and we’re excited to be your “foundation” for the wind energy movement! From design to cap, start to finish, consider it handled.

Deep foundations are demanded for wind turbines. A critical consideration in the design phase is high tensile forces, combined with horizontal loads and overturning moments. As wind turbine height and blade length continue to increase their foundations are subjected to even greater amounts of stress.

DFI is proud to bring its extensive experience in steel pile deep foundations (both helical and driven) to wind energy providers. Steel piles are an excellent alternative to concrete piles for numerous reasons, especially when concrete supply is a challenge due to accessibility and transportation.

What We Do For Wind Piling Projects

Pile Design – Our in-house team of engineers create concepts tailored to your needs and are ready to assist with up-front design and testing.

Pre-Drilling – We offer a large mobile fleet of customized air drilling units and auger drilling rigs that can handle most soil conditions.

Survey – DFI surveyors use the latest technology to provide precise layouts for both foundations and field fabrication of pile caps, guaranteeing accurate and timely results every time.

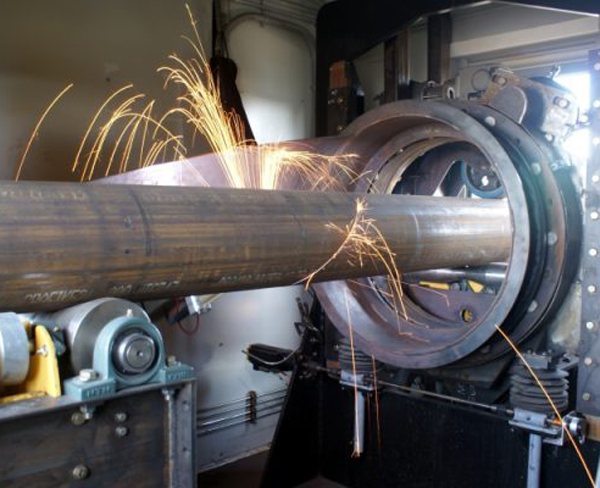

Manufacturing & Supply – Proud to own and operate our very own independent piling pipe mill in North America, intentionally designed to rapidly respond to customers’ changing needs. We also source piling materials from numerous pre-qualified mills in other countries. Additionally, DFI maintains a healthy stock of piling material to satisfy urgent project needs.

Installation – Proprietary and purpose-built equipment allow us to tackle tough terrain in remote locations, harsh climates, tight overhead spaces, and environmentally sensitive sites. Usually, we can address issues right in the field as they arise.

Testing – Our engineers use your geotechnical data and structural needs to develop a personalized load testing program that meet or exceed industry standards. Following this we execute static or dynamic tests using our proprietary installation equipment.

Cap Supply & Install – Our services end with pile cutting and capping, which reduces unnecessary delays and maintains a single point of contact for your piling project.

Pile Extraction – At the end of a pile’s life cycle or project, DFI can extract our steel piles using either vibratory or rotary methods. These piles can often be reused, and if not, recycled.

Hydrovac – DFI is proud to include hydrovac as part of our one-stop-shop suite of piling services. We also provide hydrovac for many non-piling related projects.

Why Choose DFI?