In addition to conventional steel helical piling, DFI is capable of providing bucket piles for your project needs.

What Are Bucket Piles?

Bucket piles are a niche product primarily used for T&D projects with soft and/or wet soil conditions that make auguring a hole difficult. Rather than setting a steel or wooden pole directly into the ground, the pole is set into the bucket and crushed gravel is used to fill around it. Essentially, bucket piles replace a direct embed scenario.

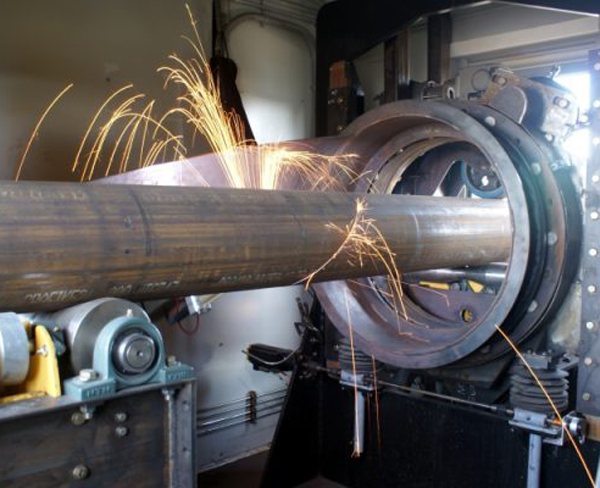

In terms of design, bucket piles can be considered two-stage piles. The first stage, the upper shaft, is called “the barrel” and has a larger pile diameter. Diameter size ranges from 610 mm (24”) to 1524 mm (60”). The second stage, the lower section, is a helical pile with a smaller diameter known as “the lead”. The most common diameter sizes are 324 mm (12 ¾ ”) or 406 mm (16”).

Other Steel Bucket Pile Applications

Bucket piles can also be used in firmer soil conditions for any free-standing pole application where high moment or lateral capacities are required, including freeway lighting, communication towers and signage. In these instances, a transition cap may be secured on top of the bucket to create a surface, then the structure is mounted/fixed to it.

The DFI Advantage – Bucket Piling Capabilities

The main advantage to bucket piles is speed. DFI can install each bucket pile in just 15 minutes (traditional methods can take 4 to 5 hours). We can also engineer non-standard pile lengths made to spec to meet your design requirements, which can minimize or reduce scraps reducing material costs.

Why Choose DFI?