The leader in steel piling foundations, DFI started in the piling business over thirty years ago with steel driven piling.

We have extensive experience with this type of piling, driving over 1.2 million steel pipe piles to-date. This equates to 12 million metres (7456 miles) of piles and 635,000 tonnes (almost 625,000 tons) of steel.

Driven piles perform exceedingly well in North America as they are well suited to diverse ground conditions.

The main benefits of steel driven piling include:

- Economic & Fast. When it comes to steel piles, fewer raw materials are needed. Piles are prefabricated offsite, stocked and ready to use. This allows for timely installation once onsite, and for testing and quality control to be done in advance.

- Timely. They can be cut, capped and used immediately.

- Environmentally friendly. Piles can be removed and reused reducing remediation costs, and they do not create spoil. By the way, DFI’s services include pile extraction.

The DFI Advantage – Our Steel Driven Capabilities

Pile Types

We offer steel pipe piles, H-Piles and steel sheet piling.

Pile Size (pipe)

- We manufacture, supply and install an industry leading pile length of 26 metres (85’) – no splicing required.

- We manufacture, supply and install piles with diameters between 114.4 mm (4 1/2”) to 914mm (36”).

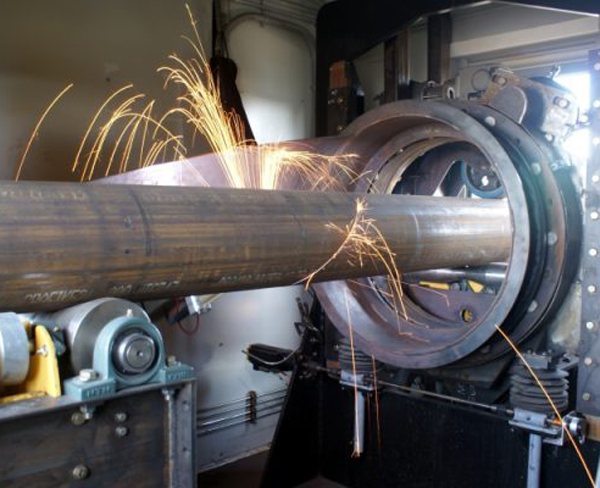

Pile Supply & Manufacturing

Think piles on demand. We’re very proud to own and operate an independent ERW steel pipe piling mill. It was intentionally designed to rapidly respond to customers’ changing project supply needs. We continually maintain industry-leading inventory levels of standard-length pipe, as well as hot-rolled coil – ready to go! Plus, we can also source sizes that we don’t make.

Pile Installation

- Our RGZ cranes can go over existing infrastructure (ex. pipelines, gas lines, pipe-racks, ditches, berms, facilities, etc.) to access hard to reach pile locations.

- Our RGZ cranes can rotate, which allow us to drive a sequence of piles from the same position, less repositioning required.

- We can install both driven and helical piles with the same rig (30 minute changeover), which decreases mobilization cost.

- We have a large fleet (over 40 units) able to handle large projects.

- Our rubber tire-mounted RGZ cranes can drive to site and haul what they need (skidsteer, leads, hammer, and piles).

- Our track-mounted RGZ cranes can go where others can’t (uneven rough terrain).

Why Choose DFI?